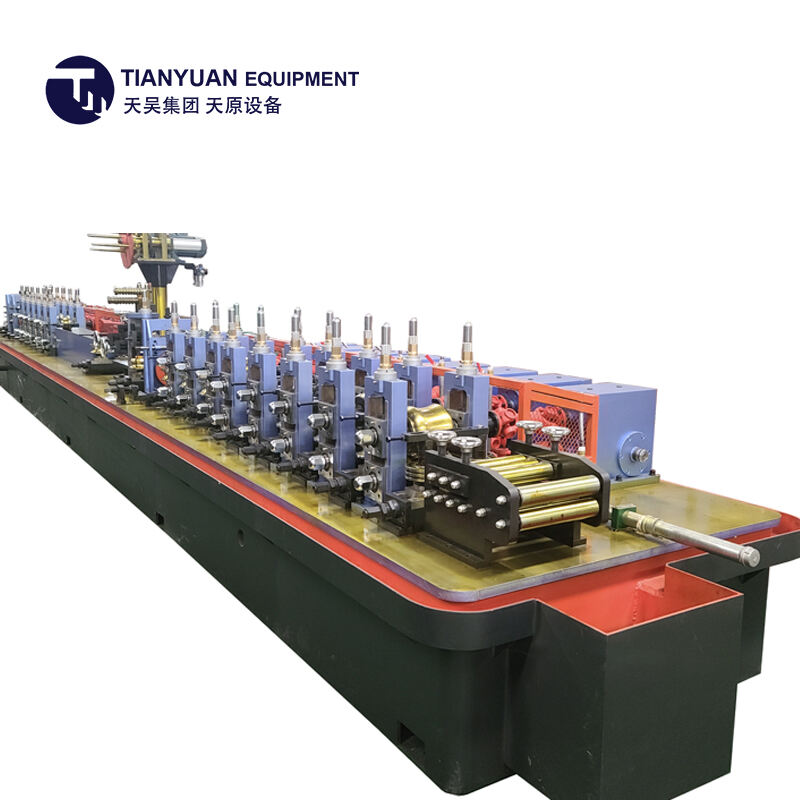

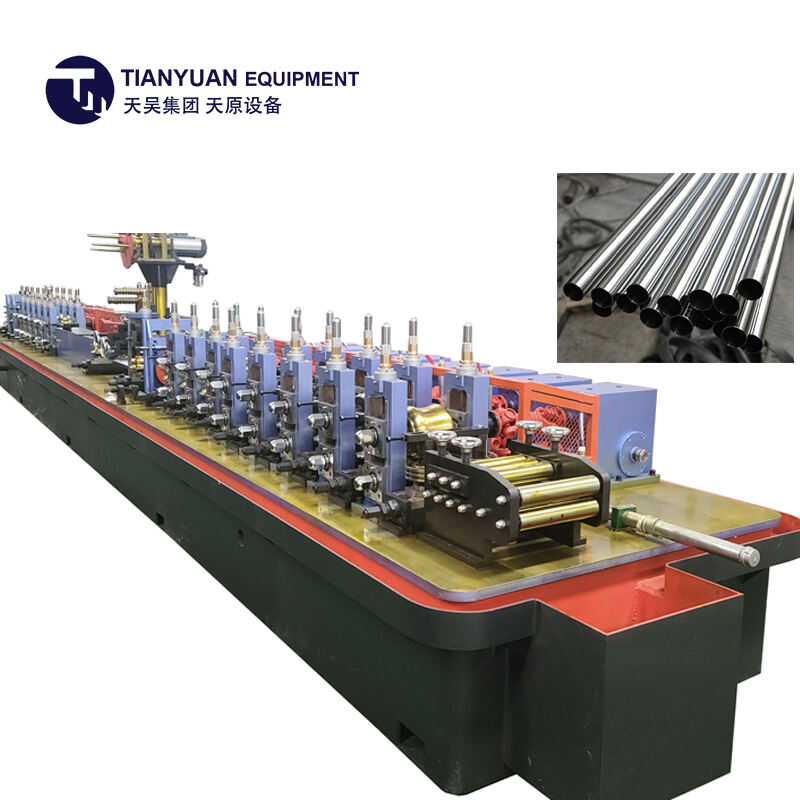

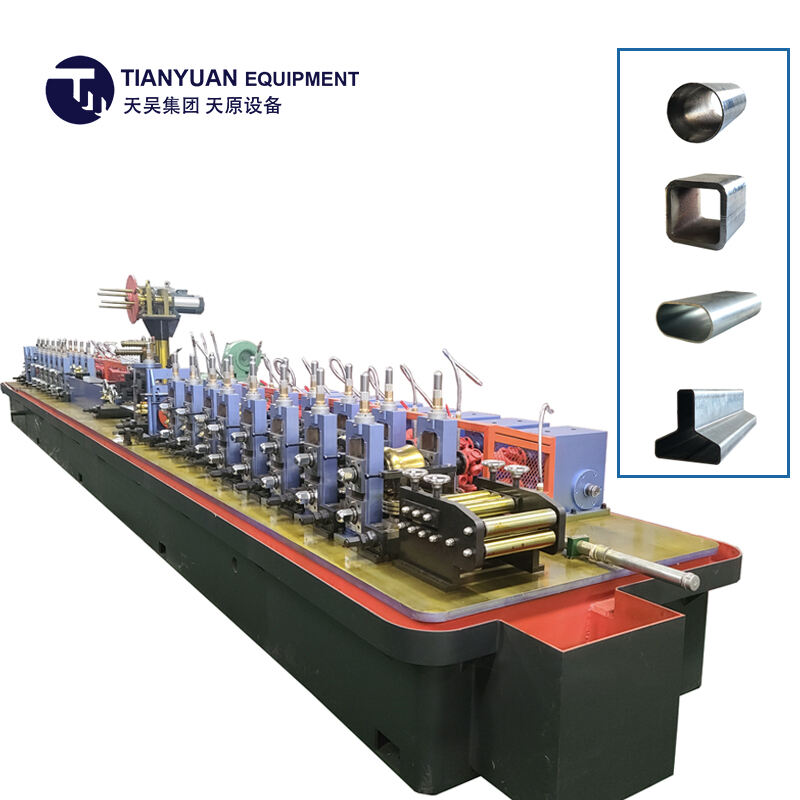

เครื่องทำท่อเหล็กคาร์บอน

เครื่องทำท่อเหล็กคาร์บอนเป็นโซลูชันการผลิตที่ซับซ้อน ออกแบบมาเพื่อผลิตท่อเหล็กคุณภาพสูงด้วยความแม่นยำและประสิทธิภาพ อุปกรณ์ขั้นสูงนี้ใช้เทคโนโลยีล้ำสมัยในการเปลี่ยนวัสดุเหล็กคาร์บอนดิบให้กลายเป็นท่อที่แข็งแรงและสม่ำเสมอผ่านกระบวนการผลิตที่ต่อเนื่อง เครื่องนี้รวมหลายขั้นตอน เช่น การป้อนวัสดุ การหล่อรูป การเชื่อม การปรับขนาด และการตกแต่ง ทั้งหมดควบคุมผ่านระบบอัตโนมัติแบบบูรณาการ ด้วยการออกแบบที่หลากหลาย สามารถผลิตท่อในเส้นผ่าศูนย์กลางและความหนาของผนังแตกต่างกันได้ ทำให้เหมาะสมสำหรับการใช้งานในอุตสาหกรรมหลากหลาย เครื่องนี้มีฟังก์ชันควบคุมที่แม่นยำเพื่อรักษาคุณภาพอย่างต่อเนื่องตลอดกระบวนการผลิต ในขณะที่เทคโนโลยีการเชื่อมขั้นสูงช่วยให้มีรอยต่อที่แข็งแรงและน่าเชื่อถือ สร้างจากชิ้นส่วนเกรดอุตสาหกรรม ระบบมีความทนทานพิเศษและต้องการการบำรุงรักษาเพียงเล็กน้อย สายการผลิตสามารถปรับแต่งด้วยคุณสมบัติเพิ่มเติม เช่น ระบบตัดอัตโนมัติ อุปกรณ์จัดแต่งปลายท่อ และสถานีตรวจสอบคุณภาพ โซลูชันที่ครอบคลุมนี้ตอบสนองอุตสาหกรรมต่างๆ ตั้งแต่การก่อสร้างและการพัฒนาโครงสร้างพื้นฐานไปจนถึงน้ำมันและก๊าซ โดยมอบท่อที่ตรงตามมาตรฐานและข้อกำหนดคุณภาพระดับนานาชาติ