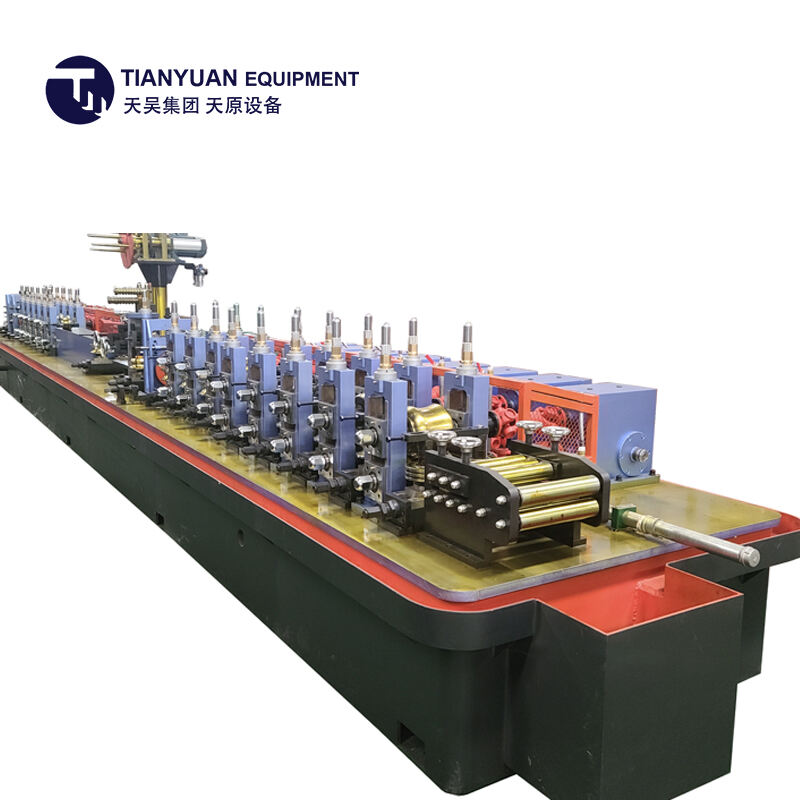

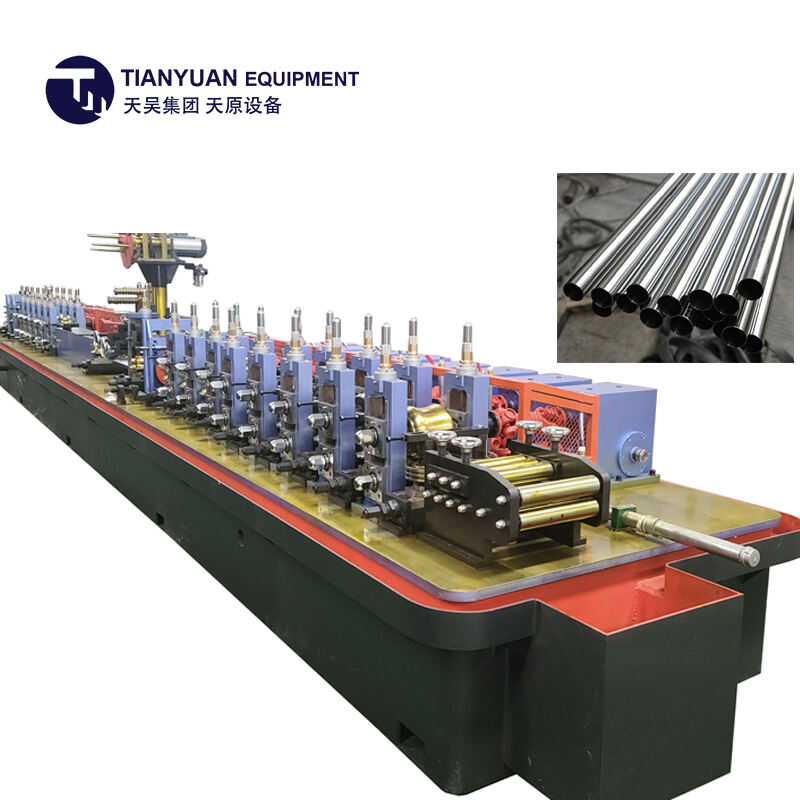

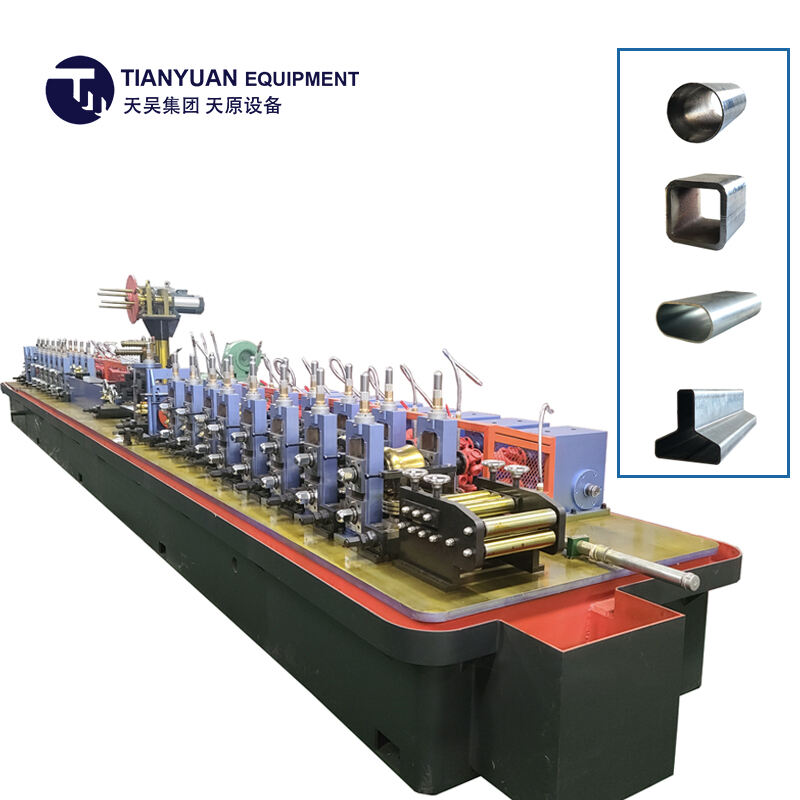

customizable carbon steel pipe making machine

The customizable carbon steel pipe making machine represents a breakthrough in modern manufacturing technology, offering unparalleled flexibility and precision in pipe production. This advanced system incorporates state-of-the-art automation features that enable continuous production of high-quality carbon steel pipes in various dimensions and specifications. The machine utilizes a sophisticated forming process that begins with raw steel strip feeding, followed by precise roll forming, high-frequency welding, and sizing operations. Its intelligent control system maintains consistent production parameters while allowing real-time adjustments to meet specific manufacturing requirements. The machine can produce pipes ranging from 20mm to 165mm in diameter, with wall thicknesses from 0.5mm to 3.0mm, making it suitable for diverse industrial applications. Enhanced with modern safety features and energy-efficient components, the system ensures optimal performance while minimizing operational costs. The machine's modular design facilitates easy maintenance and quick format changes, reducing downtime and increasing productivity. Advanced quality control mechanisms, including automated inspection systems and precision measurement tools, guarantee that every pipe meets stringent industry standards.