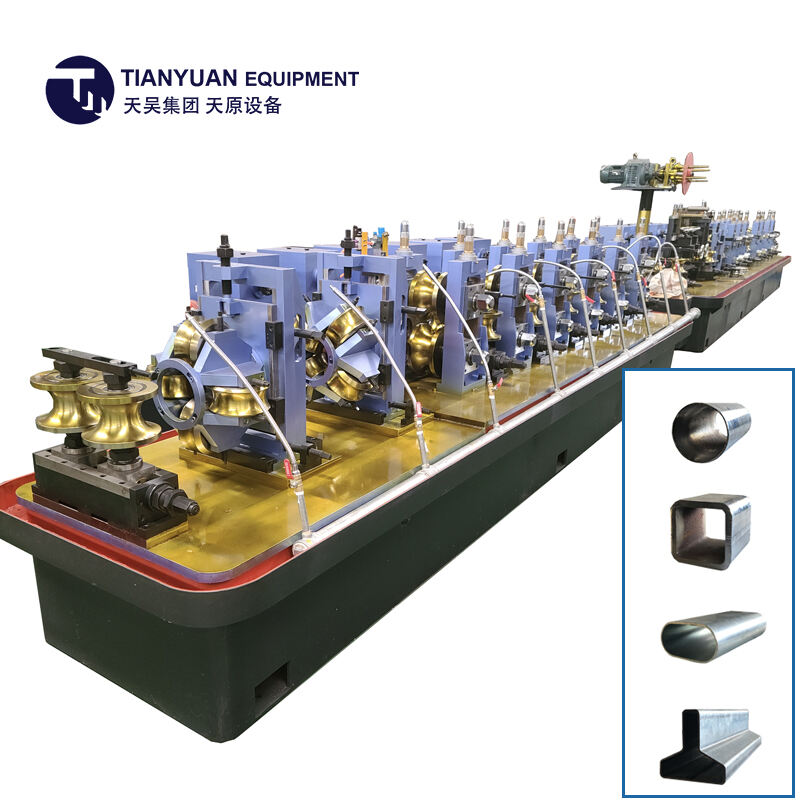

makinang pang-gawa ng gi pipe

Ang makina para sa paggawa ng GI pipe ay kinakatawan bilang isang pinakamabagong solusyon sa industriya ng metal fabrication, disenyo upang magbunga ng mataas na kalidad na galvanized iron pipes na may katatagan at kasiyahan. Ang mabilis na makina na ito ay nag-iintegrate ng maraming proseso, kabilang ang pag-uncoil, pagsasaak, pagweld, pagsize, at galvanization, lahat sa loob ng isang streamlines production line. Gumagamit ang sistema ng mga sofistikadong mekanismo ng kontrol na siguradong magkakaroon ng konsistente na diyametro ng pipe, kapaligiran ng pader, at surface finish sa buong proseso ng paggawa. Ang malakas na konstraksyon ng makina ay may mga komponente na pang-industriya, kaya gumamit ng patuloy na siklo ng produksyon habang panatilihing maikli ang toleransiya. Ito ay nakakapagpasok ng iba't ibang sukat ng pipe, karaniwang mula sa 15mm hanggang 200mm sa diyametro, na may pambago-bagong setting ng kapaligiran ng pader upang tugunan ang mga iba't ibang spesipikasyon ng industriya. Ang automatikong sistema ng kontrol ay sumusubaybay sa kritikal na parameter tulad ng temperatura ng pagweld, forming pressure, at galvanization consistency, siguradong bawat pipe ay nakakamit ang matalinghagang pamantayan ng kalidad. Ang solusyon sa paggawa na ito ay sumasama ng advanced na mga tampok ng seguridad, kabilang ang emergency stop systems, temperatura monitoring, at protective guards, nagiging ganito ang epektibo at operator-friendly. Ang modular na disenyo ng makina ay nagpapahintulot ng madaling maintenance access at mabilis na pagbabago sa pagitan ng iba't ibang spesipikasyon ng pipe, minimizeng production downtime. Ang kanyang kakayahang magpalaki ay nagiging kanya angkop para sa mga aplikasyon sa construction, plumbing, industrial infrastructure, at agricultural sectors.