excellent erw tube mill

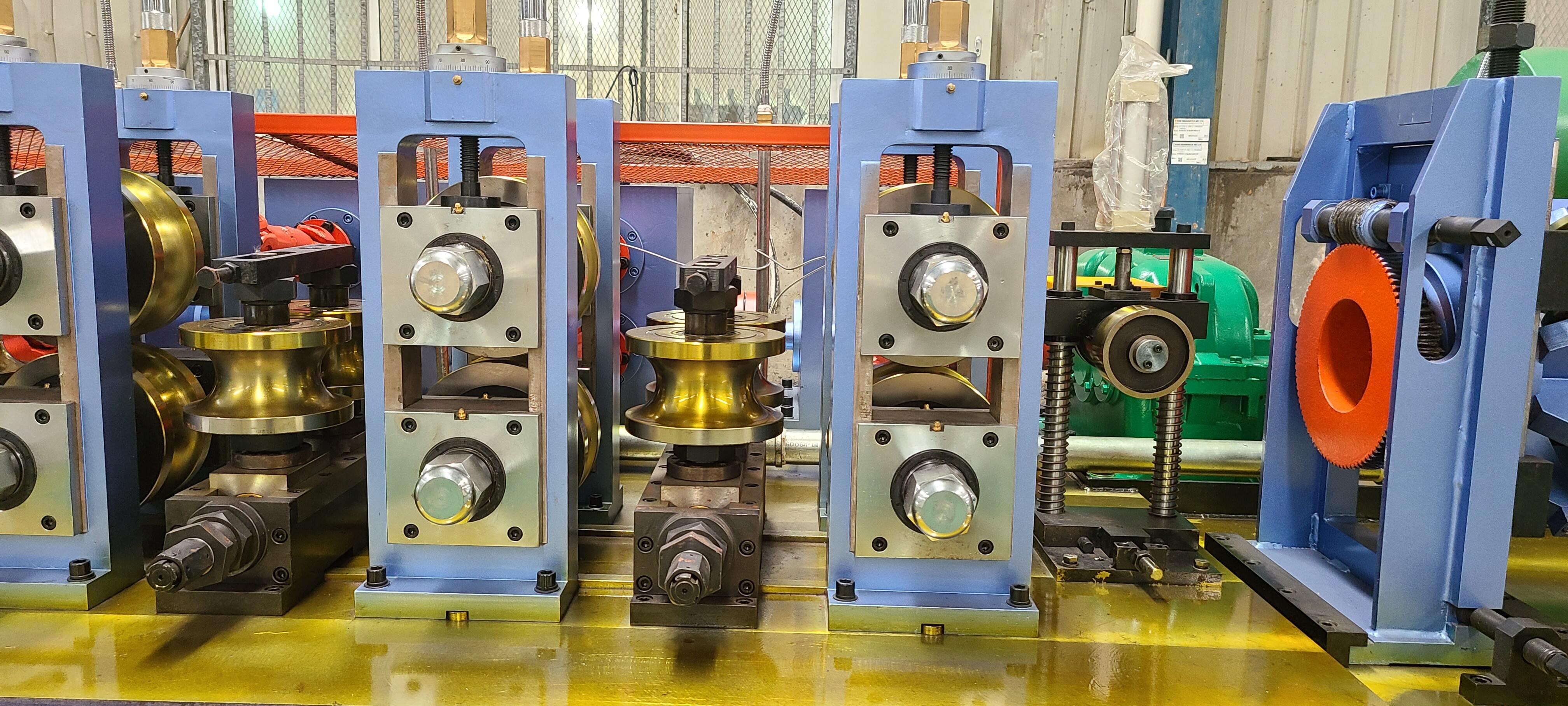

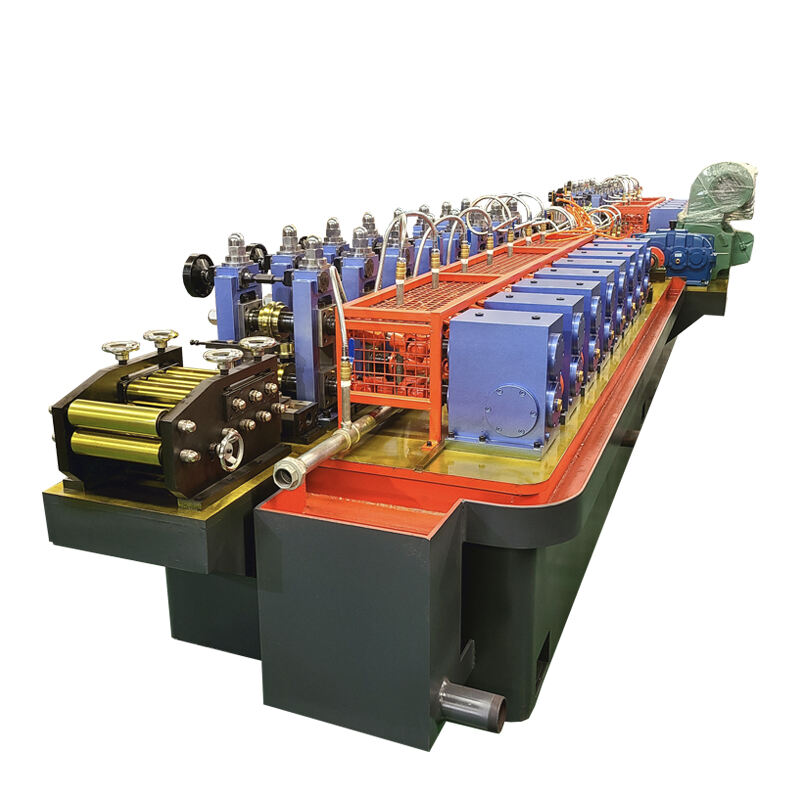

The excellent ERW tube mill represents a cutting-edge manufacturing solution for producing high-quality welded steel tubes with precision and efficiency. This advanced system utilizes electric resistance welding technology to create seamless joints in steel tubes, ensuring superior structural integrity and reliability. The mill operates through a comprehensive process that begins with strip steel feeding, proceeds through precise forming stages, and culminates in high-frequency welding. The mill's sophisticated control systems maintain exact dimensional tolerances throughout the production process, while its advanced cooling mechanisms ensure optimal metallurgical properties in the finished tubes. Modern ERW tube mills incorporate state-of-the-art automation features, including real-time monitoring systems and quality control checkpoints that guarantee consistent product quality. The equipment is designed to handle various steel grades and can produce tubes ranging from small diameters to larger sizes, making it versatile for different industrial applications. The integration of smart manufacturing technologies enables precise control over welding parameters, forming accuracy, and production speed, resulting in tubes that meet stringent international quality standards.