reliable erw tube mill

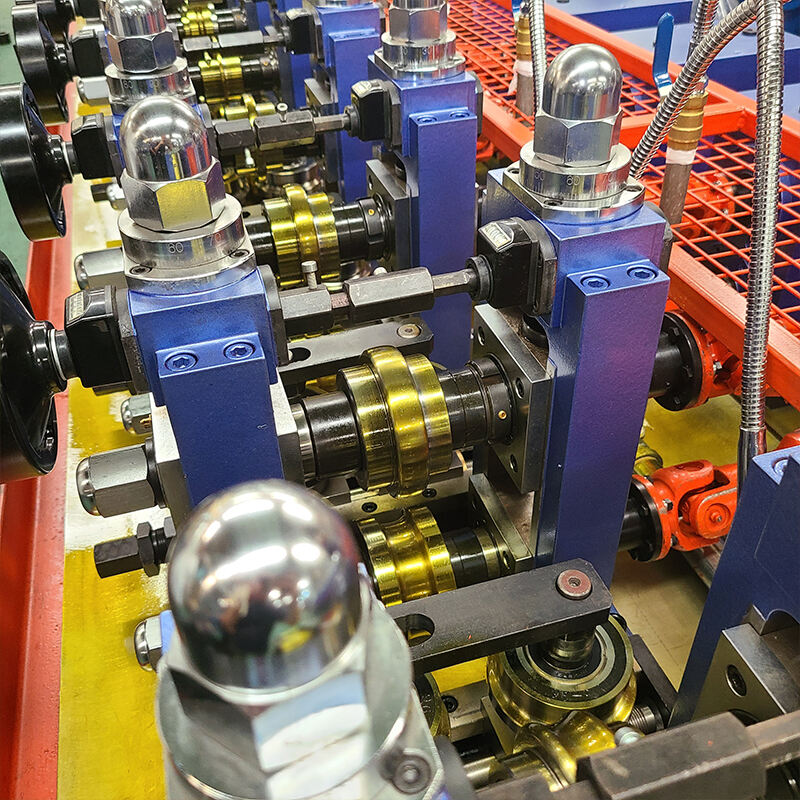

The reliable ERW tube mill represents a cutting-edge manufacturing solution designed for producing high-quality welded steel tubes with precision and efficiency. This advanced system utilizes electrical resistance welding technology to create seamless joints in steel tubes, ensuring superior structural integrity and durability. The mill incorporates sophisticated forming stages that gradually shape flat steel strips into perfectly rounded tubes through a series of carefully calibrated roller sets. Essential components include the strip accumulator, edge milling station, high-frequency welding system, and various post-weld treatment stations. The process begins with precise edge preparation, followed by progressive forming, welding, and finishing operations, all controlled by advanced automation systems. The mill's capability to maintain consistent welding temperatures and pressure ensures optimal molecular bonding, resulting in welds that meet or exceed industry standards. Modern ERW tube mills feature real-time quality monitoring systems, automated dimensional control, and quick-change tooling for enhanced productivity. These mills can process various steel grades and produce tubes ranging from small diameters to large structural sections, making them versatile for multiple industrial applications including construction, automotive, oil and gas, and furniture manufacturing.