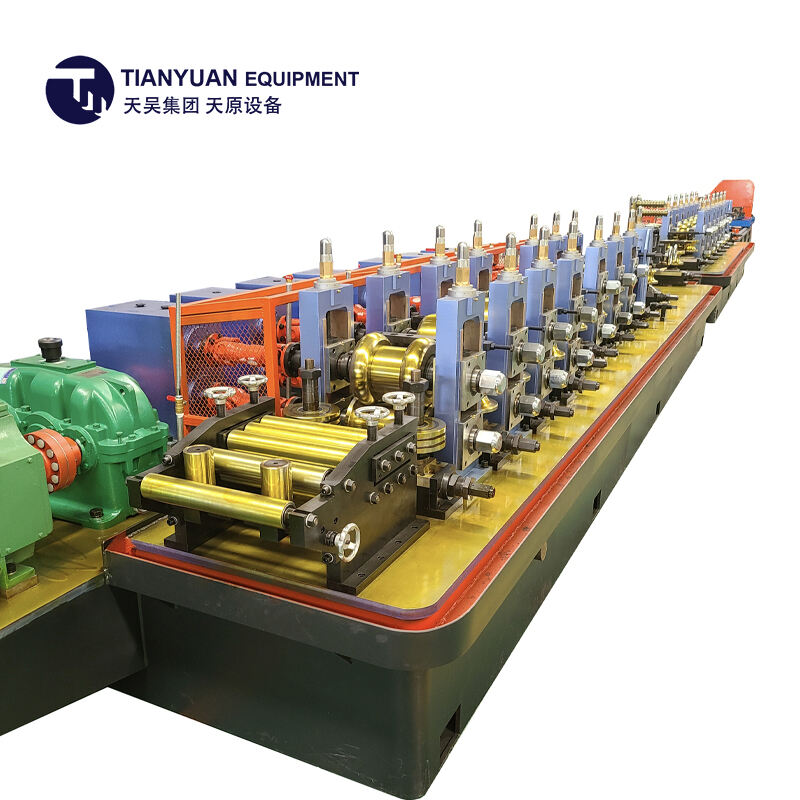

high quality erw tube mill

The high quality ERW tube mill represents a sophisticated manufacturing system designed for precise and efficient production of electric resistance welded tubes. This advanced machinery utilizes state-of-the-art technology to transform flat steel strips into perfectly welded tubes through a continuous process. The mill incorporates multiple forming stations that gradually shape the material, followed by high-frequency welding technology that ensures strong, reliable seams. The system features automated controls for maintaining exact dimensional tolerances, sophisticated monitoring systems for weld quality, and integrated cutting mechanisms for achieving precise length specifications. The mill's capabilities typically extend to producing tubes ranging from 20mm to 219mm in diameter, with wall thicknesses from 0.8mm to 8mm, making it versatile for various industrial applications. Notable features include digital control systems for maintaining consistent production parameters, advanced cooling systems for optimal welding conditions, and comprehensive quality control mechanisms that ensure each tube meets stringent industry standards. The mill's design emphasizes efficiency and reliability, incorporating features like quick-change tooling systems for minimal downtime during size changes and automated material handling systems for continuous operation.