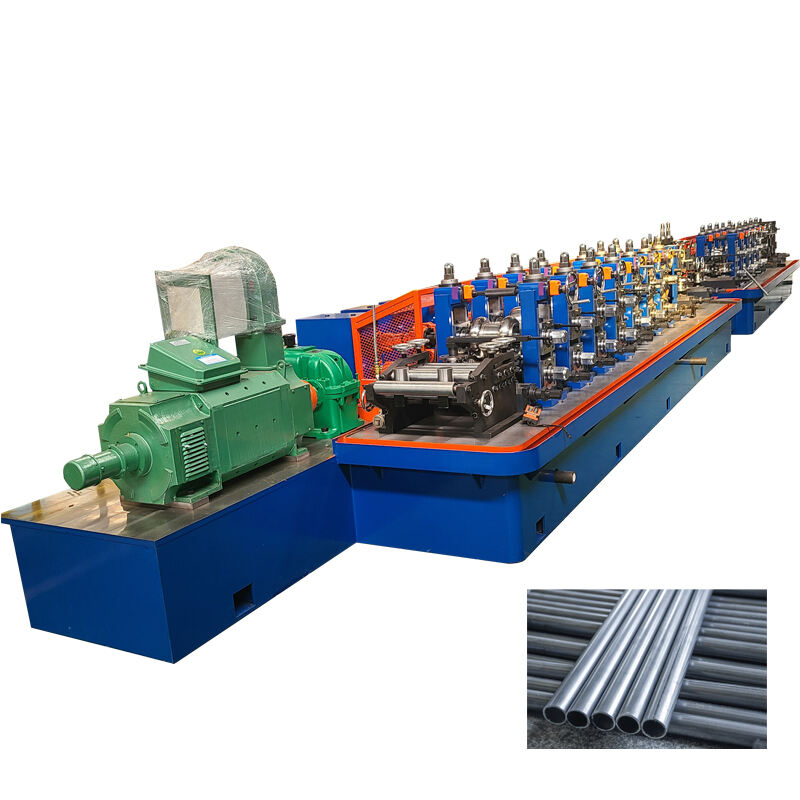

safe and reliable erw tube mill

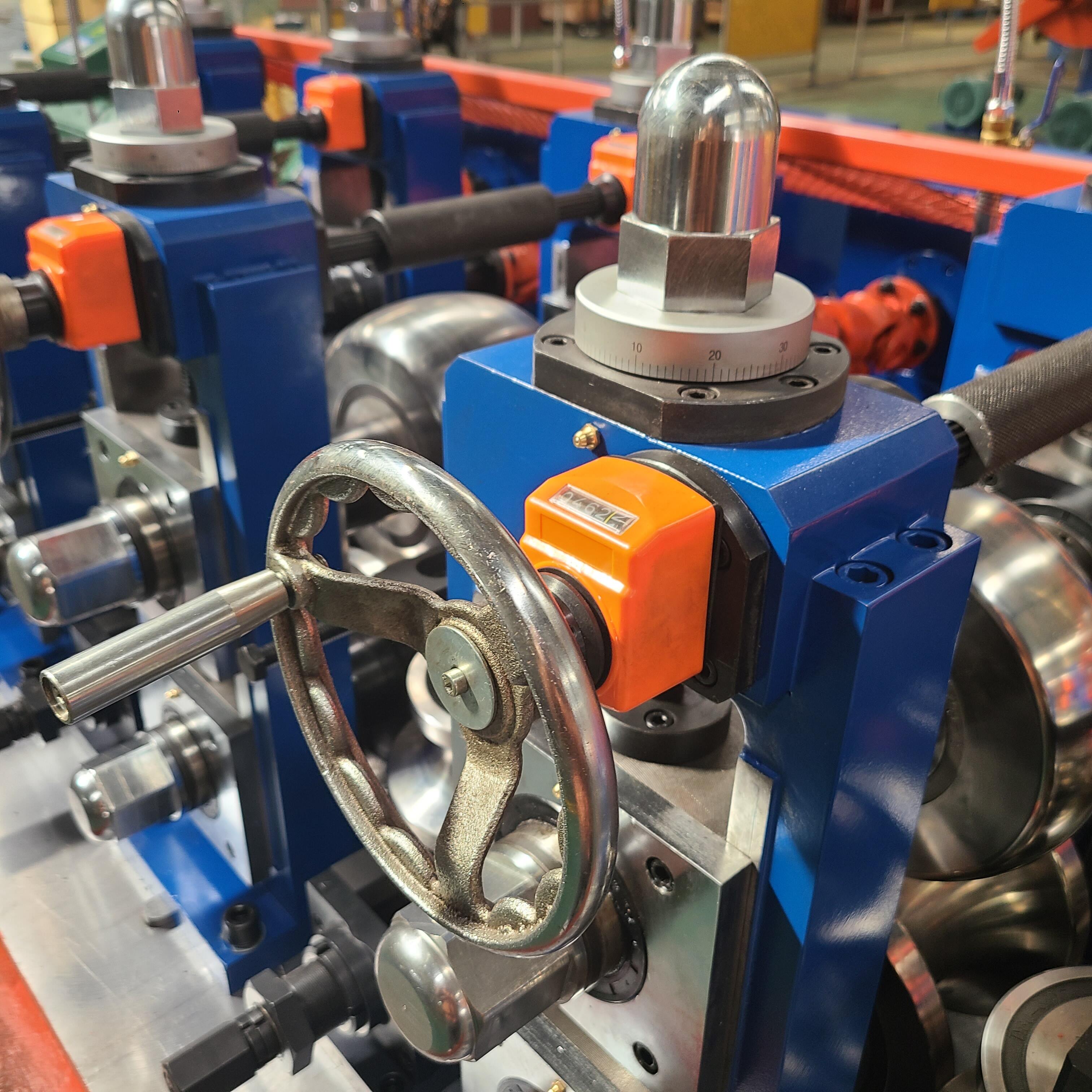

The safe and reliable ERW tube mill represents a cutting-edge solution in modern tubular manufacturing. This advanced system integrates high-frequency welding technology with precise forming processes to create high-quality welded steel tubes. The mill incorporates multiple forming stations that gradually shape flat steel strips into round tubes through a series of carefully calibrated rollers. Each station is equipped with advanced safety features, including emergency stop systems and protective guards. The mill's sophisticated control system maintains consistent welding parameters, ensuring uniform weld quality throughout production. Notable technological features include automatic strip centering mechanisms, precise edge preparation systems, and advanced cooling systems for the welding zone. The equipment is designed for continuous operation, capable of producing tubes ranging from 20mm to 219mm in diameter, with wall thicknesses from 0.8mm to 8mm. Applications span across various industries, including construction, automotive, furniture manufacturing, and infrastructure development. The mill's versatility allows for the production of round, square, and rectangular tubes, meeting diverse market demands while maintaining stringent quality standards.