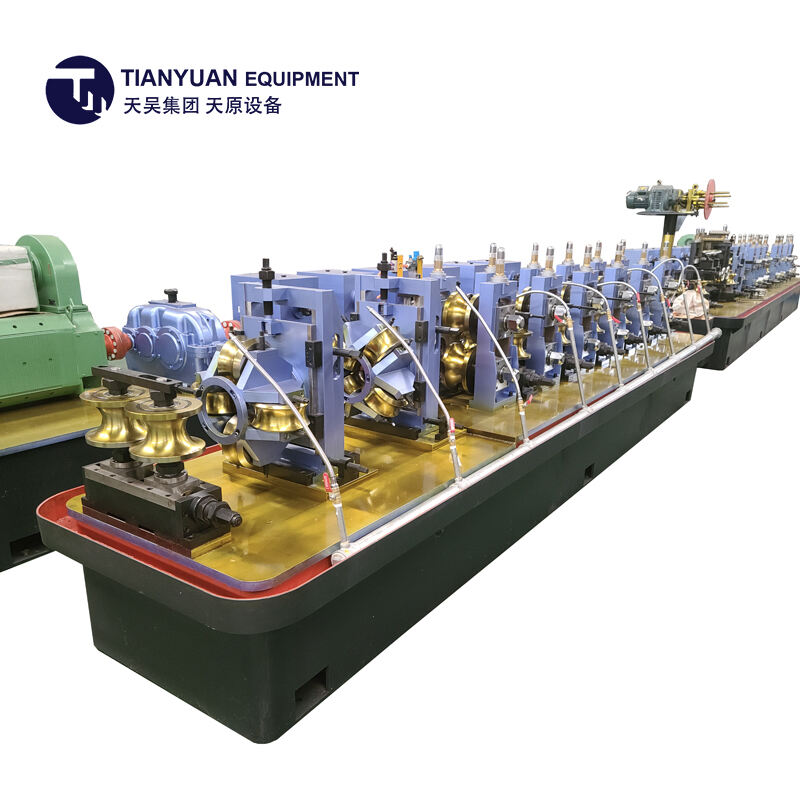

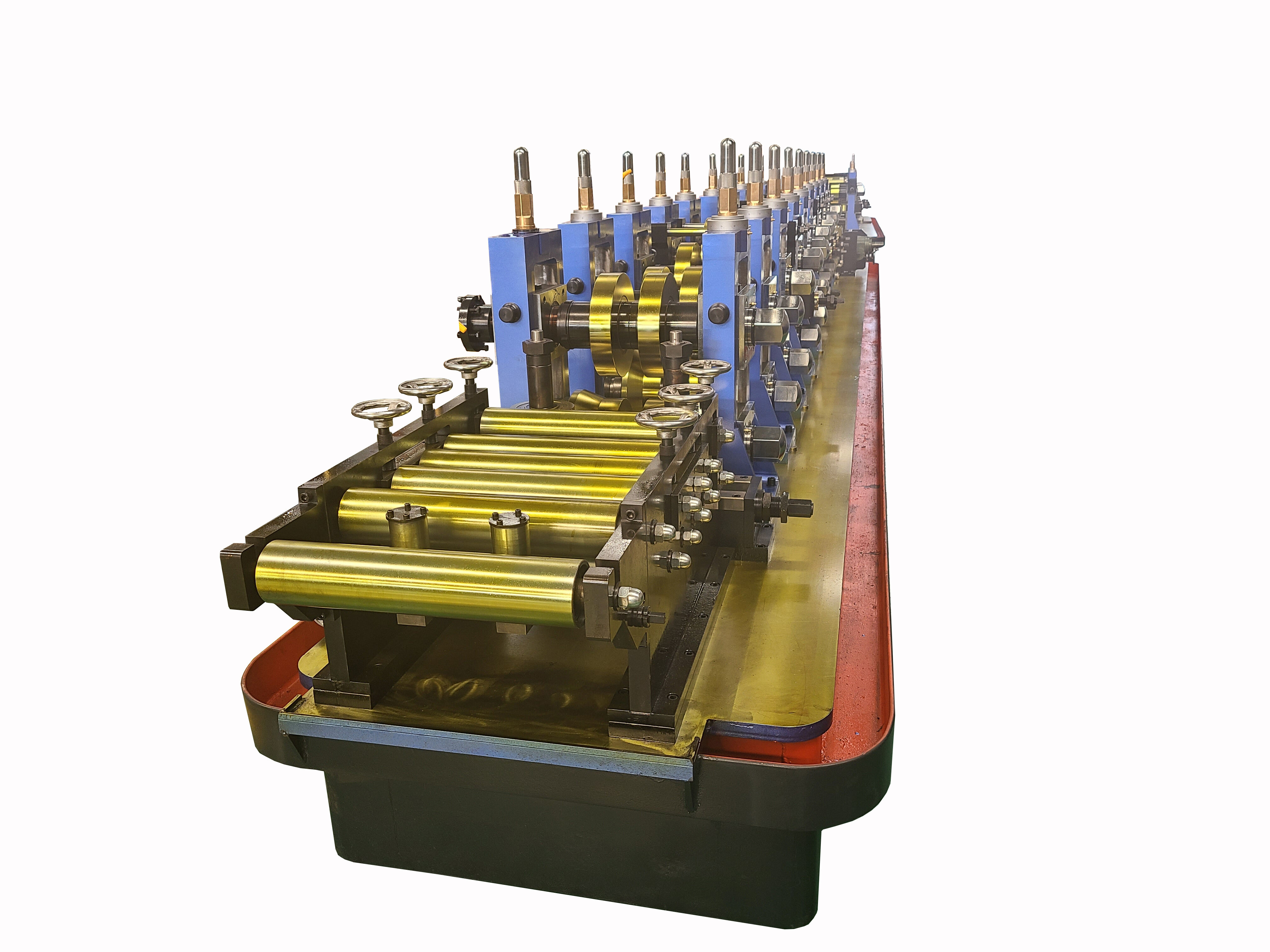

solution erw tube mill

The ERW tube mill represents a cutting-edge solution in pipe manufacturing technology, offering a highly efficient and precise method for producing electric resistance welded tubes. This advanced system integrates multiple stages of forming, welding, and finishing operations into a continuous production line. The process begins with strip steel feeding through a series of forming rolls that gradually shape the material into a tubular form. The edges are then welded using electric resistance welding technology, which creates a strong, uniform seam without additional filler material. The mill incorporates sophisticated control systems that monitor and adjust welding parameters in real-time, ensuring consistent weld quality. Modern ERW tube mills feature high-speed production capabilities, with some systems achieving production speeds of up to 120 meters per minute. The technology is particularly valuable in manufacturing pipes for various applications, including structural supports, fluid transportation, and mechanical components. The finished products meet international quality standards and can be produced in a wide range of sizes, typically from 0.5 to 24 inches in diameter.