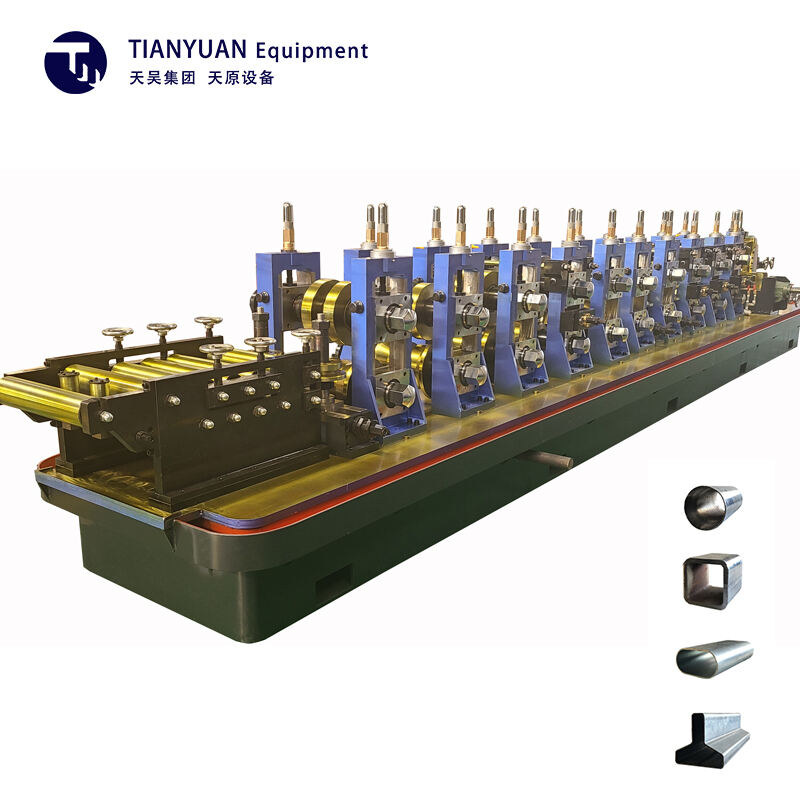

popular erw tube mill

The ERW tube mill represents a cutting-edge solution in modern manufacturing, offering high-precision production of welded steel tubes through electrical resistance welding technology. This sophisticated equipment combines automated feeding, forming, welding, and sizing operations in a continuous production line. The mill utilizes advanced forming technology with multiple roll stands that gradually shape flat steel strips into round tubes, while maintaining precise dimensional control throughout the process. The electrical resistance welding system generates concentrated heat at the strip edges, creating a strong and uniform weld seam without additional filler material. Modern ERW tube mills feature digital control systems that monitor and adjust crucial parameters such as welding temperature, pressure, and speed in real-time, ensuring consistent product quality. These mills can process various steel grades and produce tubes ranging from small diameters of 10mm to larger sizes exceeding 400mm, with wall thicknesses from 0.4mm to 12mm. The versatility of ERW tube mills makes them essential in manufacturing pipes for construction, automotive, furniture, and various industrial applications, offering both efficiency and cost-effectiveness in tube production.