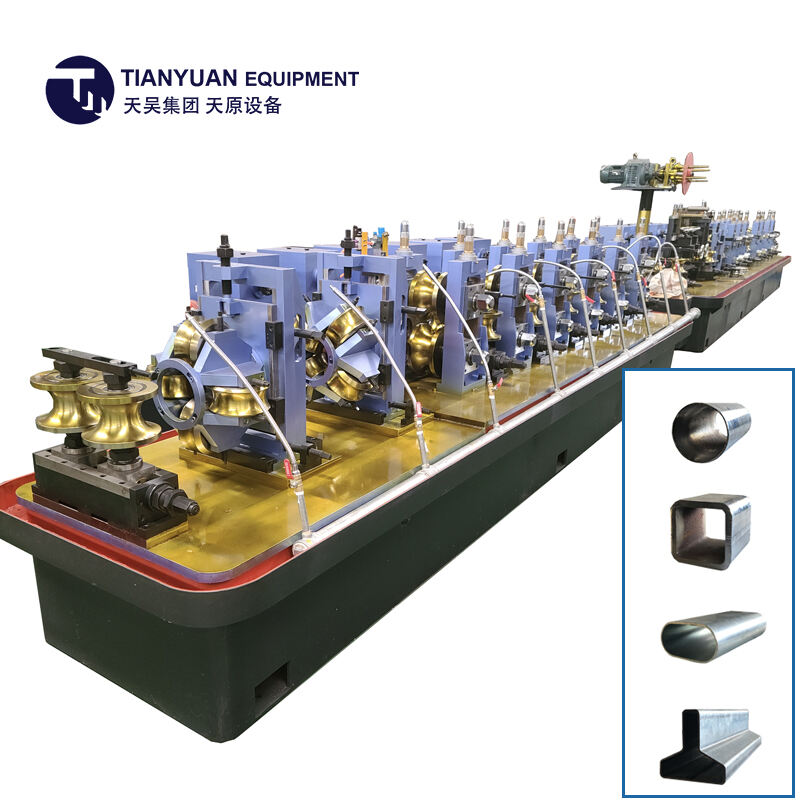

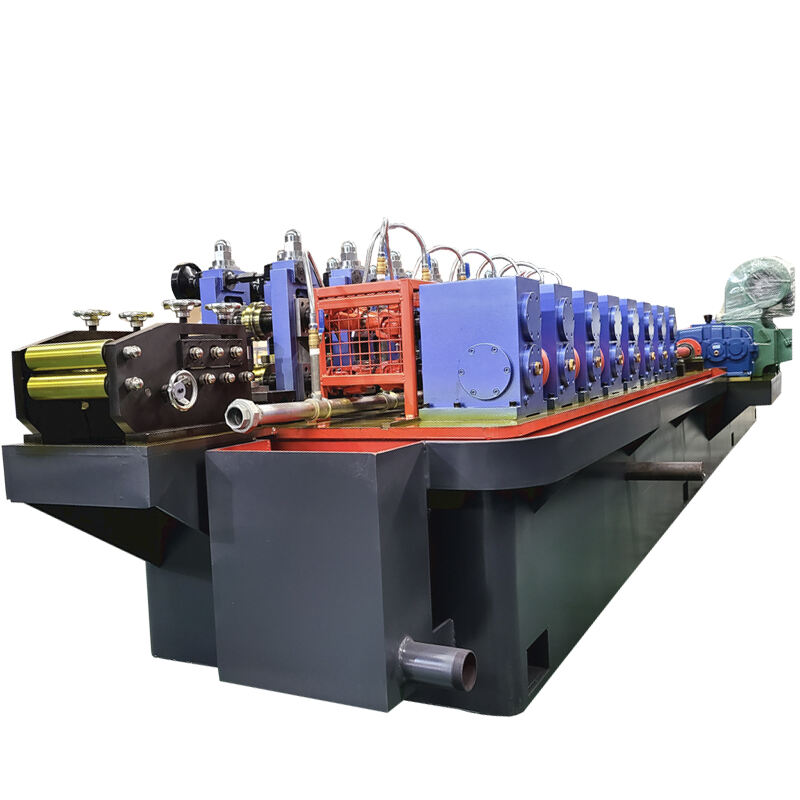

quality erw tube mill

The quality ERW tube mill represents a sophisticated manufacturing system designed for producing high-precision electric resistance welded tubes. This advanced equipment combines multiple stages of forming, welding, and finishing processes to create tubes with exceptional dimensional accuracy and structural integrity. The mill utilizes advanced frequency technology for precise welding control, ensuring consistent weld quality throughout the production process. The system incorporates automated monitoring systems that continuously assess tube formation, weld quality, and dimensional parameters, maintaining strict quality standards. The mill's modular design allows for quick size changes and efficient production adjustments, making it suitable for various production requirements. Modern ERW tube mills feature enhanced forming sections with optimized roll designs that ensure smooth material flow and superior tube roundness. The equipment typically includes advanced cutting systems, enabling precise length control and clean end cuts. These mills are capable of processing various material grades and thicknesses, from standard carbon steel to specialized alloys, with production speeds optimized for different tube specifications.