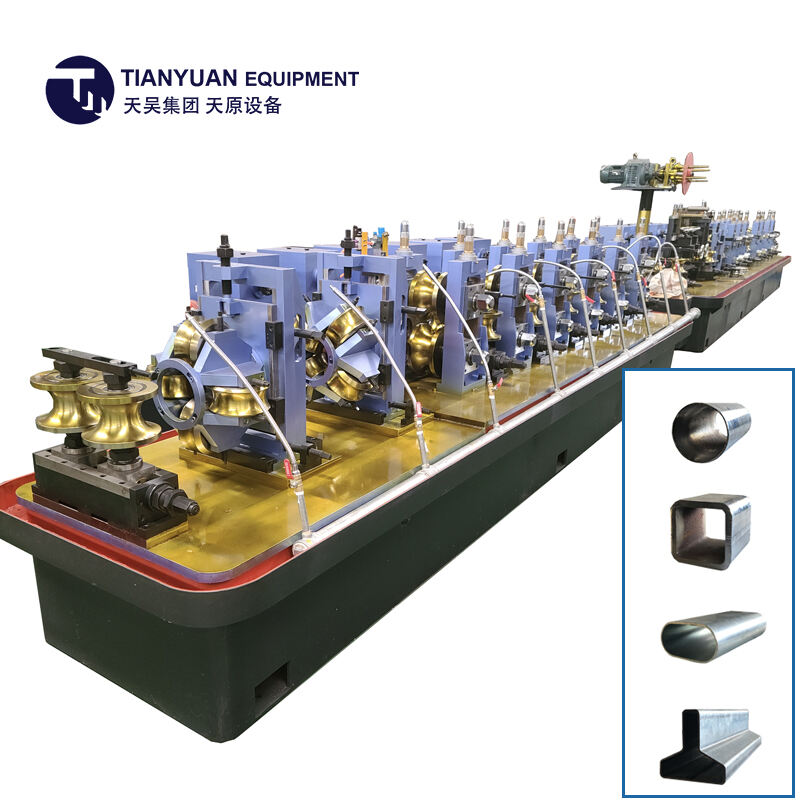

excellent performance erw tube mill

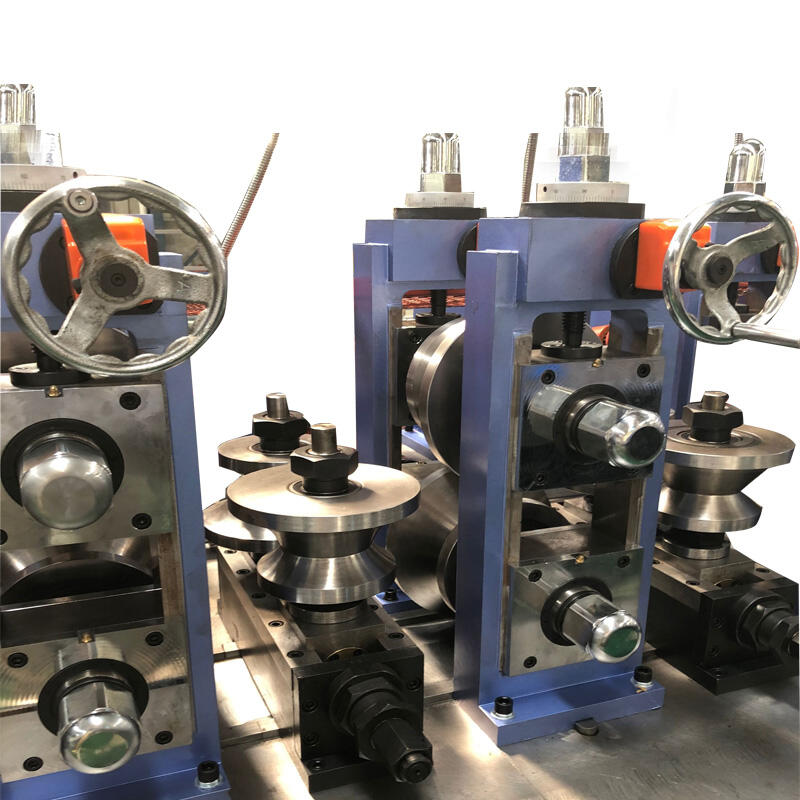

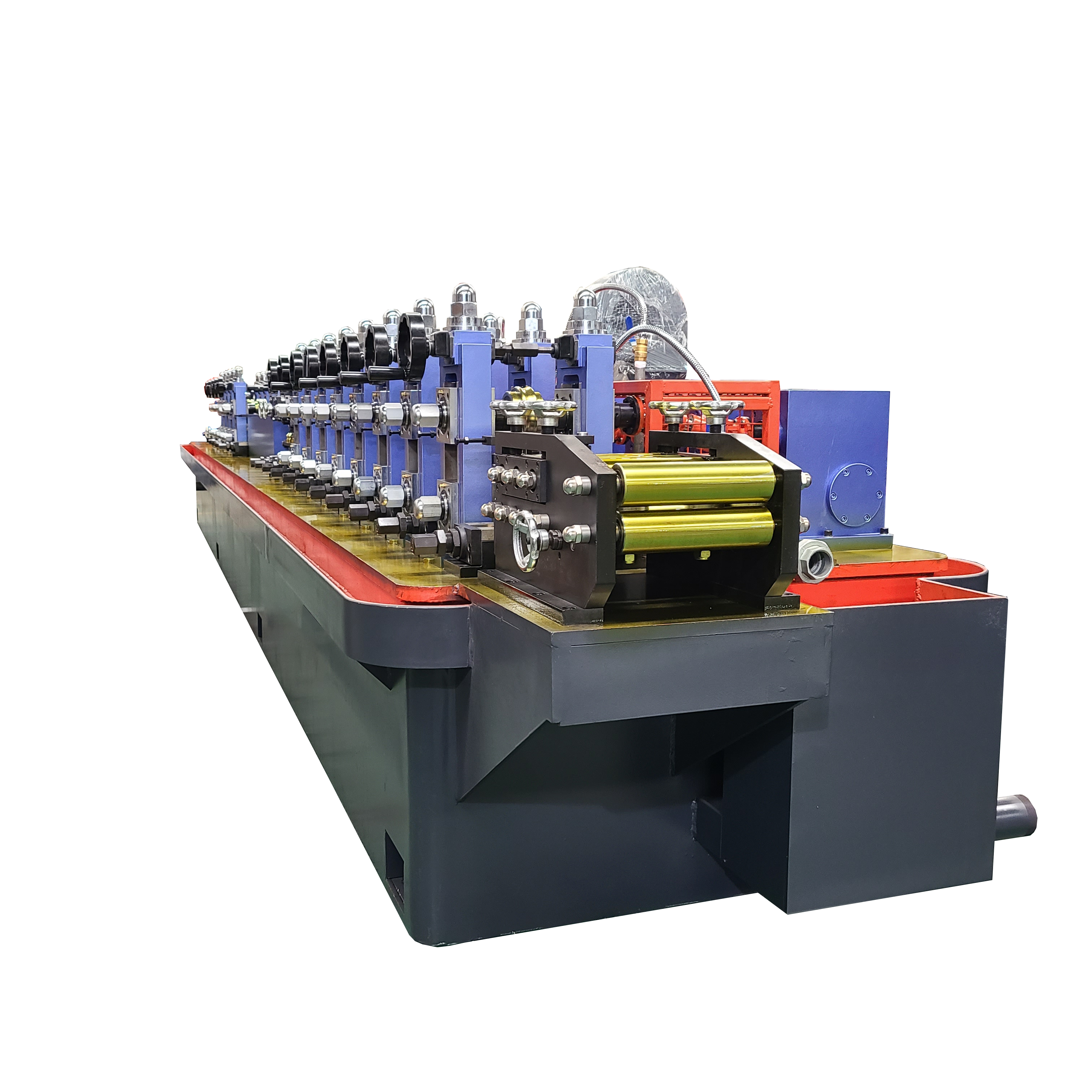

The excellent performance ERW tube mill represents a cutting-edge solution in tube manufacturing technology, delivering precision-engineered products with remarkable consistency. This advanced manufacturing system combines high-frequency welding technology with automated controls to produce high-quality welded steel tubes. The mill operates through a systematic process that begins with strip feeding, followed by precise forming, welding, sizing, and final cutting to desired specifications. Its sophisticated control systems maintain optimal welding parameters, ensuring superior weld strength and structural integrity. The mill's advanced forming section utilizes multiple roll stands arranged in a precise configuration to gradually shape flat steel strips into perfectly round tubes. Notable features include automatic width adjustment capabilities, precision temperature control during welding, and integrated quality monitoring systems. The equipment is capable of producing tubes ranging from 20mm to 165mm in diameter, with wall thicknesses from 1.0mm to 6.0mm. Applications span across various industries, including construction, automotive, furniture manufacturing, and infrastructure development. The mill's versatility allows for the production of both standard and custom tube specifications, meeting diverse market demands while maintaining consistent quality standards.