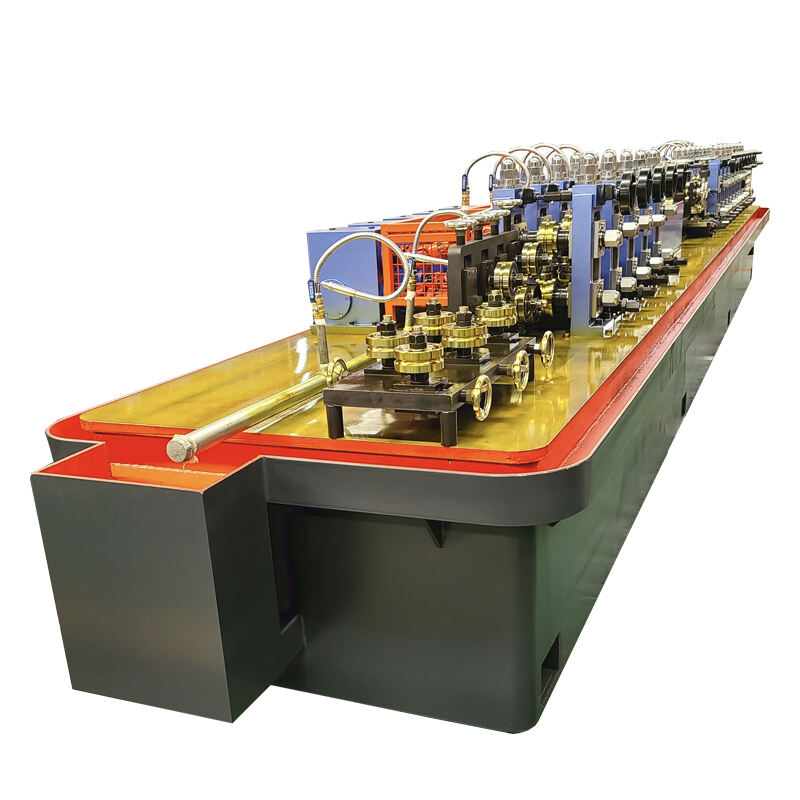

solution gi pipe making machine

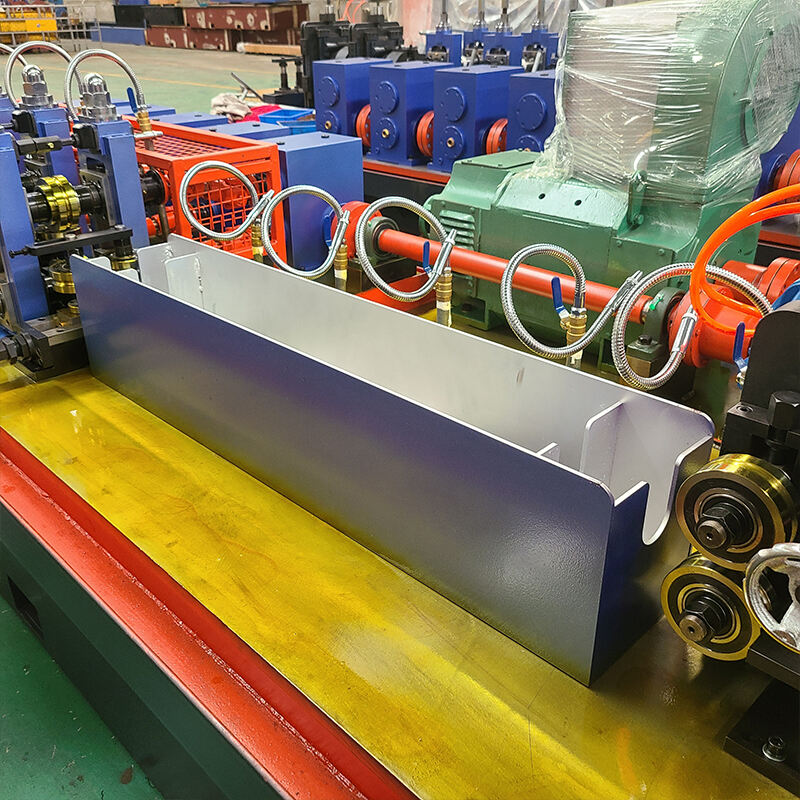

The solution GI pipe making machine represents a cutting-edge manufacturing system designed for producing galvanized iron pipes with precision and efficiency. This advanced equipment integrates multiple processes, including decoiling, forming, welding, sizing, and galvanizing, all in a seamless production line. The machine utilizes high-frequency welding technology to ensure strong, uniform seams while maintaining consistent pipe dimensions. Its automated control system features touch-screen interfaces and PLC programming, enabling operators to monitor and adjust production parameters in real-time. The machine can handle various pipe specifications, typically producing pipes ranging from 1/2 inch to 4 inches in diameter, with wall thicknesses from 1.5mm to 4mm. The production line incorporates advanced galvanizing technology that ensures uniform zinc coating application, providing superior corrosion resistance. The system's quality control mechanisms, including ultrasonic testing and dimensional verification, guarantee that each pipe meets industry standards. With production speeds reaching up to 50 meters per minute, this machine significantly enhances manufacturing efficiency while maintaining product quality.