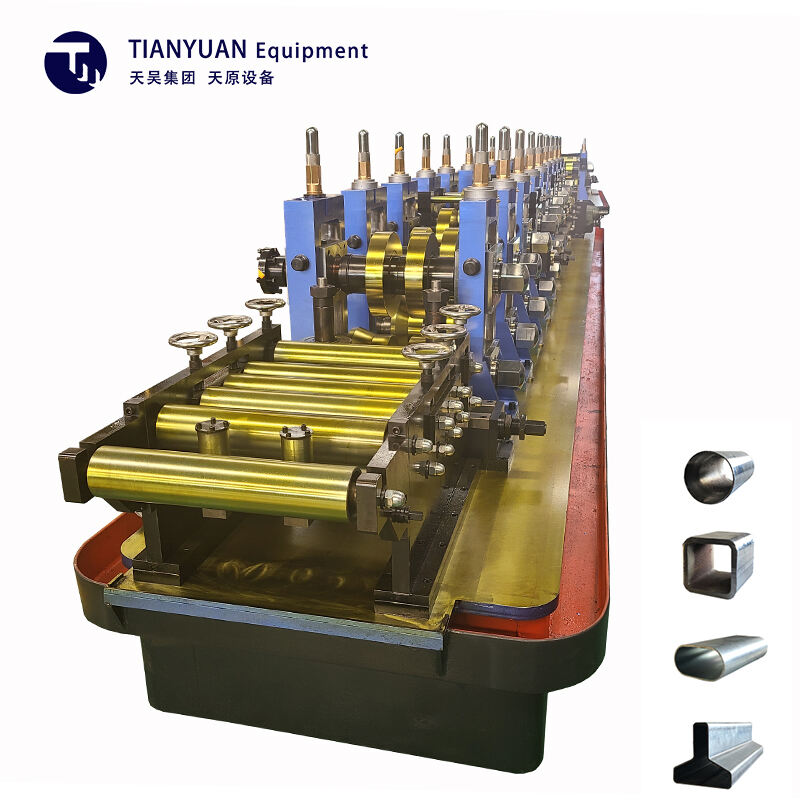

dernier modèle de machine à fabriquer des tubes en acier galvanisé

La dernière conception de la machine de fabrication de tubes en tôle galvanisée représente une avancée significative dans la technologie de fabrication de tubes, intégrant des fonctionnalités de pointe pour améliorer la productivité et la précision. Cette machine innovante utilise des systèmes d'automatisation avancés pour rationaliser le processus de production de tubes en acier galvanisé, de l'alimentation en matériau à l'inspection finale du produit. Les fonctions principales de la machine incluent l'alimentation automatique en matériaux, une mise en forme précise grâce à plusieurs stations de rouleaux, un soudage haute fréquence et des systèmes de refroidissement sophistiqués. Ses caractéristiques technologiques englobent des interfaces de contrôle numérique, des capacités de surveillance en temps réel et des mécanismes de contrôle de pression adaptatif qui assurent une qualité constante des tubes. La machine peut traiter différentes épaisseurs de matériaux allant de 0,5 mm à 3,0 mm et produit des tubes avec des diamètres allant de 15 mm à 76 mm. La ligne de production intègre une technologie de soudage de pointe avec des systèmes automatisés de contrôle qualité, garantissant que chaque tube respecte les normes internationales. Les applications couvrent plusieurs secteurs, y compris la construction, le développement des infrastructures, l'irrigation agricole et les systèmes de transport de fluides industriels. La polyvalence de la machine permet des changements rapides entre différentes spécifications de tubes, ce qui la rend idéale pour les fabricants répondant à des demandes de marché variées.