стабильный erw трубный станок

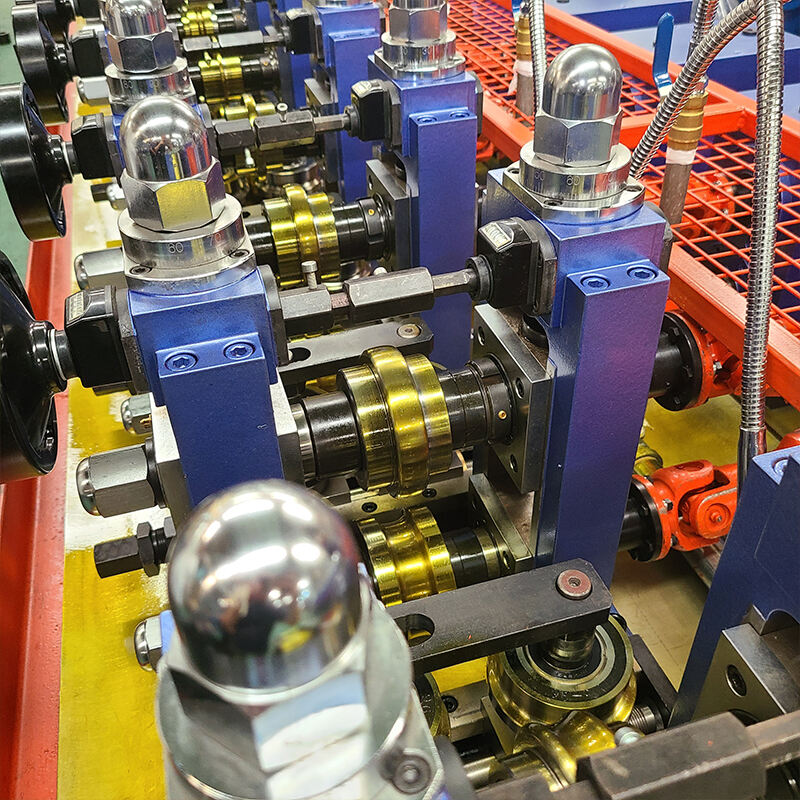

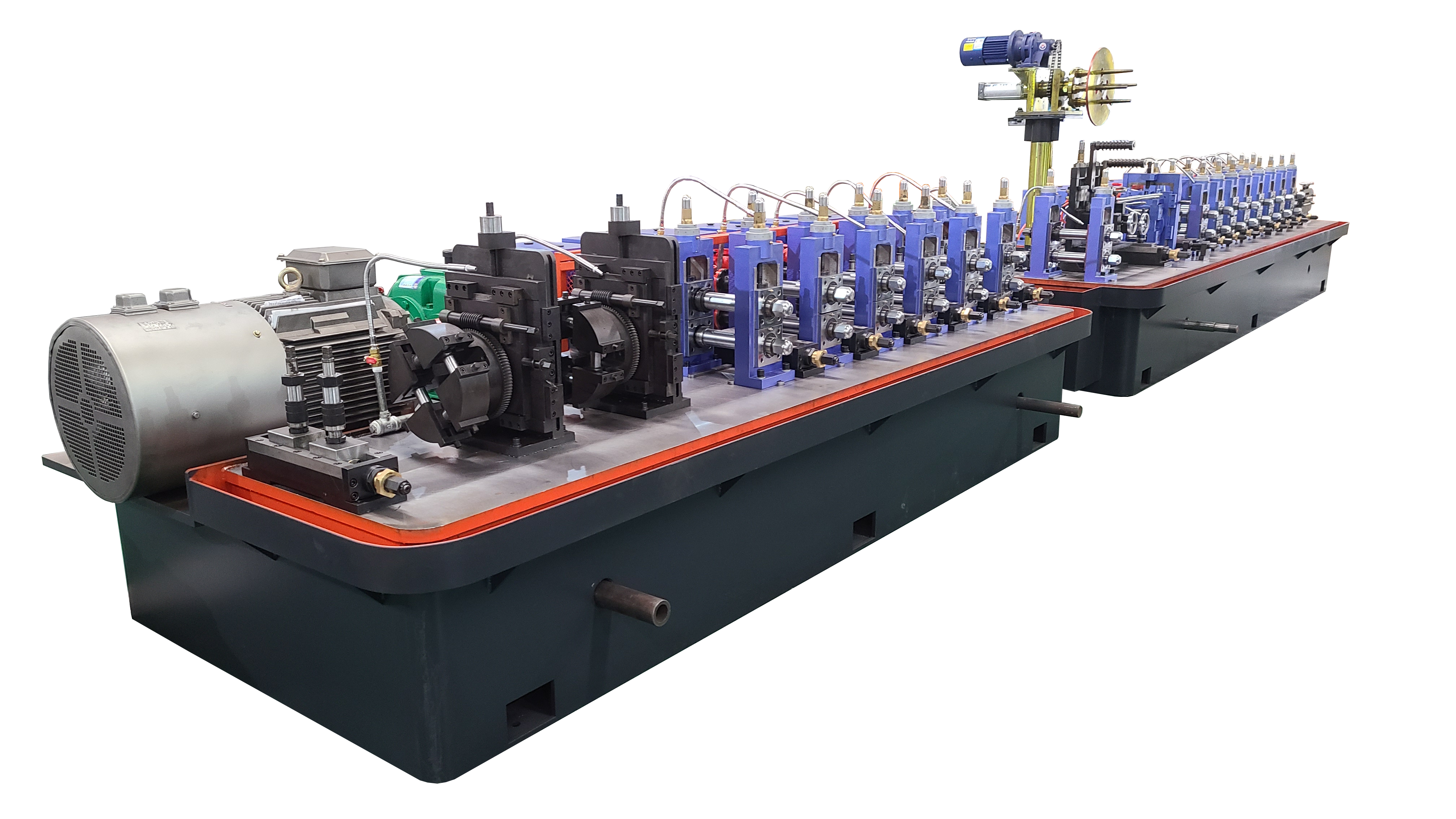

Стабильный трубопрокатный стан ERW - это передовое производственное решение, предназначенное для изготовления высококачественных сварных стальных труб с исключительной точностью и последовательностью. Этот современный комплекс включает в себя передовые технологии электросварки сопротивлением для создания бесшовных соединений в металлических трубах. Стан работает по систематическому процессу, который начинается с подачи полосовой стали, продолжается через этапы точного формирования и завершается высокочастотной сваркой. Оборудование оснащено сложными системами управления, которые поддерживают оптимальные параметры сварки на протяжении всего цикла производства, обеспечивая постоянное качество сварных швов. Одним из самых примечательных аспектов является его способность обрабатывать различные толщины материала и размеры труб при сохранении стабильных скоростей работы до 120 метров в минуту. Система включает продвинутые секции формования и выравнивания, которые гарантируют размерную точность и конструкционную прочность конечного продукта. Современные станы ERW оснащены автоматизированными системами контроля качества, включающими ультразвуковой контроль и методы индукционного испытания для проверки целостности шва в реальном времени. Эти станы находят широкое применение в отраслях, охватывающих автомобилестроение, строительство, производство мебели и развитие инфраструктуры. Многогранность стабильного трубопрокатного стана ERW позволяет производить как круглые, так и профилированные трубы, удовлетворяя разнообразным промышленным требованиям при сохранении высокой эффективности и минимальных потерь материалов.