erw tube mill

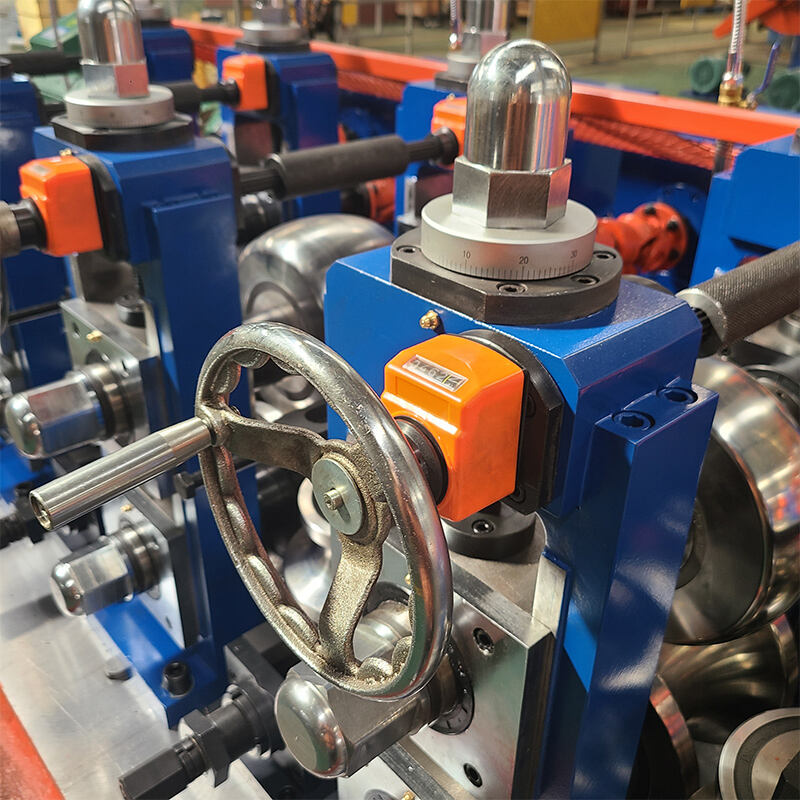

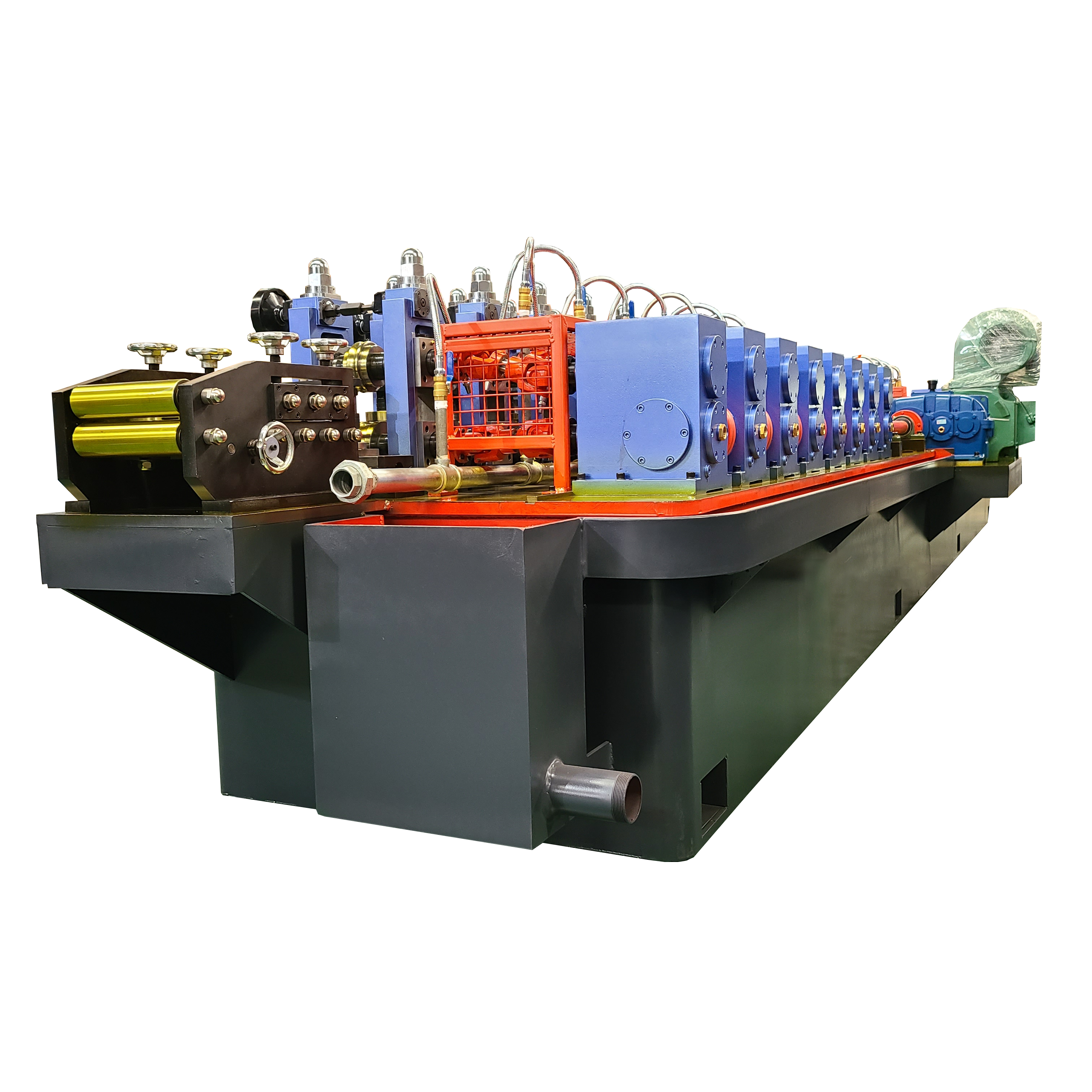

The ERW (Electric Resistance Welding) tube mill represents a cutting-edge manufacturing system designed for producing high-quality welded steel tubes efficiently and precisely. This sophisticated equipment utilizes electrical resistance welding technology to transform flat steel strips into round, square, or rectangular tubes. The process begins with the continuous feeding of steel strip through a series of forming rolls that gradually shape the material into a tubular form. The edges are then brought together and welded using high-frequency electrical current, which creates a strong and uniform seam without the need for additional filler material. Modern ERW tube mills incorporate advanced control systems and automation features, enabling precise adjustment of welding parameters, speed, and temperature control. The equipment typically includes multiple stations for forming, welding, sizing, and finishing operations, ensuring consistent product quality. These mills can process various steel grades and thicknesses, making them versatile for different industrial applications, from construction and automotive to furniture and mechanical engineering. The finished tubes undergo rigorous quality control measures, including online testing systems that verify weld integrity and dimensional accuracy.