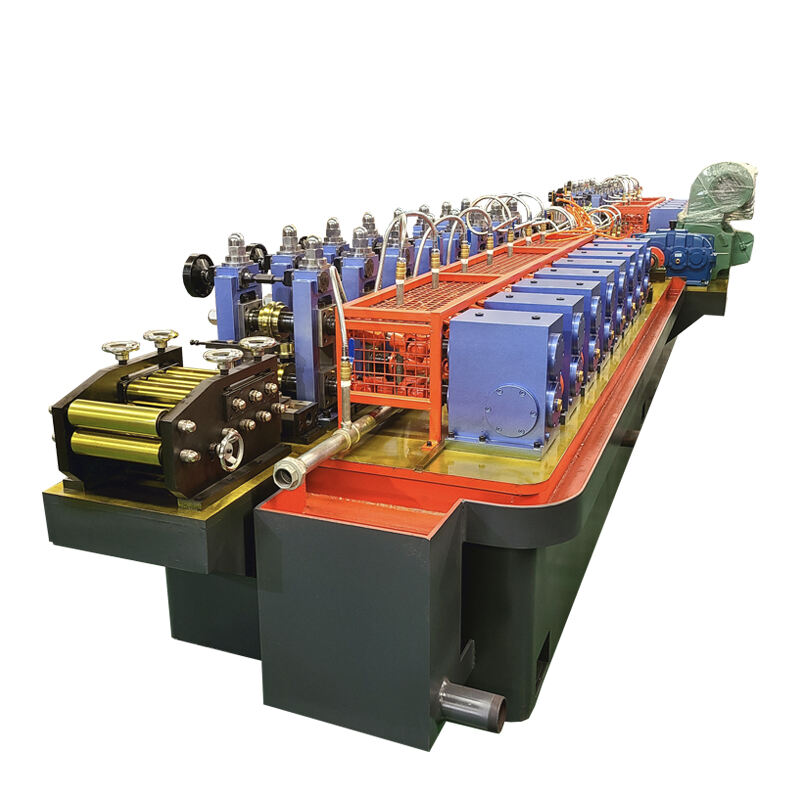

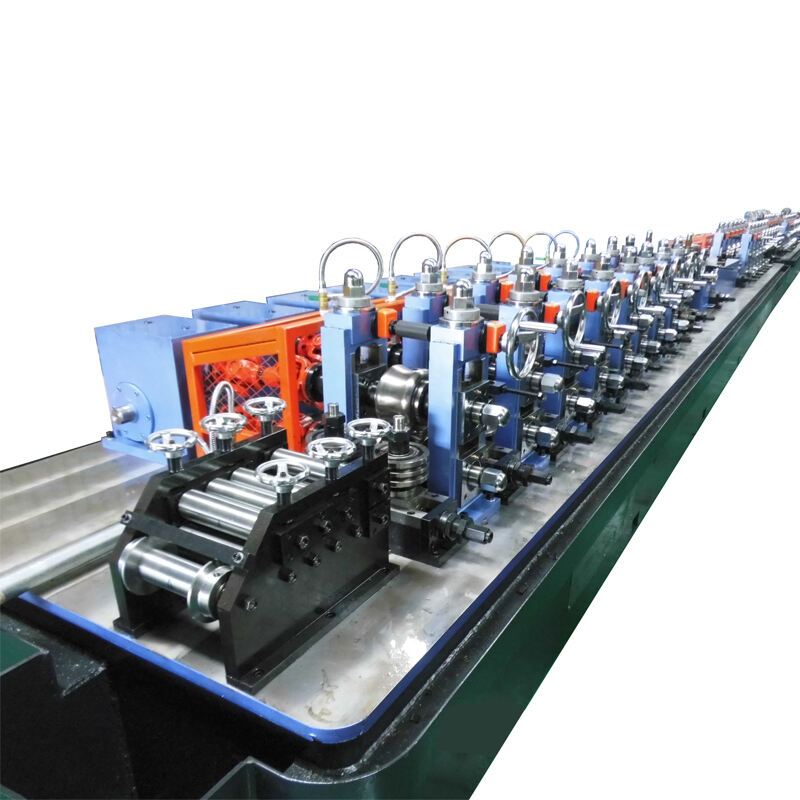

customizable erw tube mill

The customizable ERW tube mill represents a advanced manufacturing solution designed for producing high-quality welded steel tubes with precision and efficiency. This versatile system integrates cutting-edge technologies to transform flat steel strips into perfectly formed and welded tubes through electrical resistance welding (ERW). The mill's customizable features allow manufacturers to adjust various parameters including tube dimensions, wall thickness, and production speeds to meet specific project requirements. The process begins with the decoiling of steel strips, followed by precise edge preparation, forming through multiple roll stations, and high-frequency welding. Quality control systems, including online inspection equipment, ensure consistent weld quality and dimensional accuracy. The mill can accommodate various material grades and specifications, making it suitable for producing tubes used in construction, automotive, furniture, and infrastructure applications. Advanced automation features enable smooth operation with minimal manual intervention, while the modular design facilitates maintenance and future upgrades. The system's robust construction ensures long-term reliability and consistent production quality, making it an ideal choice for manufacturers seeking versatile tube production capabilities.